Digitally Transforming Aerospace Inspections

RESEARCH COLLABORATION

A cutting-edge 3D imaging technology called NeRF (Neural Radiance Fields), will be harnessed to drive the digital transformation of aerospace inspections as part of new research. The project is being funded by the Aerospace Technology Institute (ATI) and the National Aerospace Technology Exploitation Programme (NATEP), with research being carried out by our digital solutions team and the University of Derby.

This research collaboration will explore the use of NeRFs to semi-automatically transform imagery and videos of advanced aerospace parts into high-quality 3D digital representations. These can be used to track the condition and degradation of such parts over time in order to enhance efficiency and decision-making within quality inspection and airline fleet management.

NeRF is a cutting-edge technique that generates 3D representations of an object from a partial set of 2D images by using advanced machine learning. The technology is designed to offer a generalised approach to 3D object modelling and can struggle to handle highly complex geometries such as specialised aerospace components. As part of the research collaboration, this research is focused on improving the speed and performance of the NeRF algorithm to support its application within the high-tech aerospace industry, improving processes forever.

INSPECTOR

We have supported the aerospace sector for over 20 years and specialise in developing operational and data-driven solutions that help to streamline and improve processes, such as digital twin and Internet of Things applications.

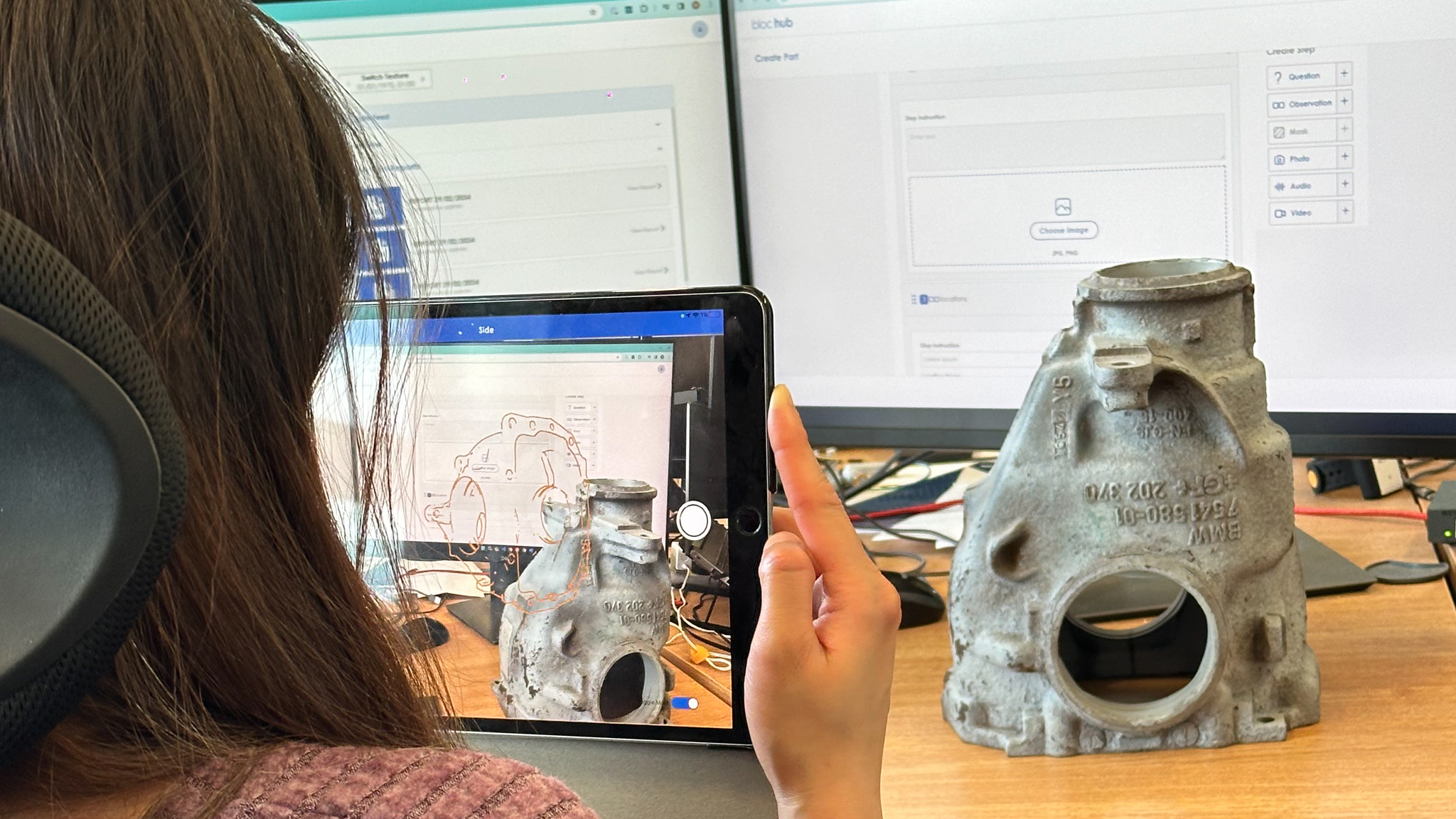

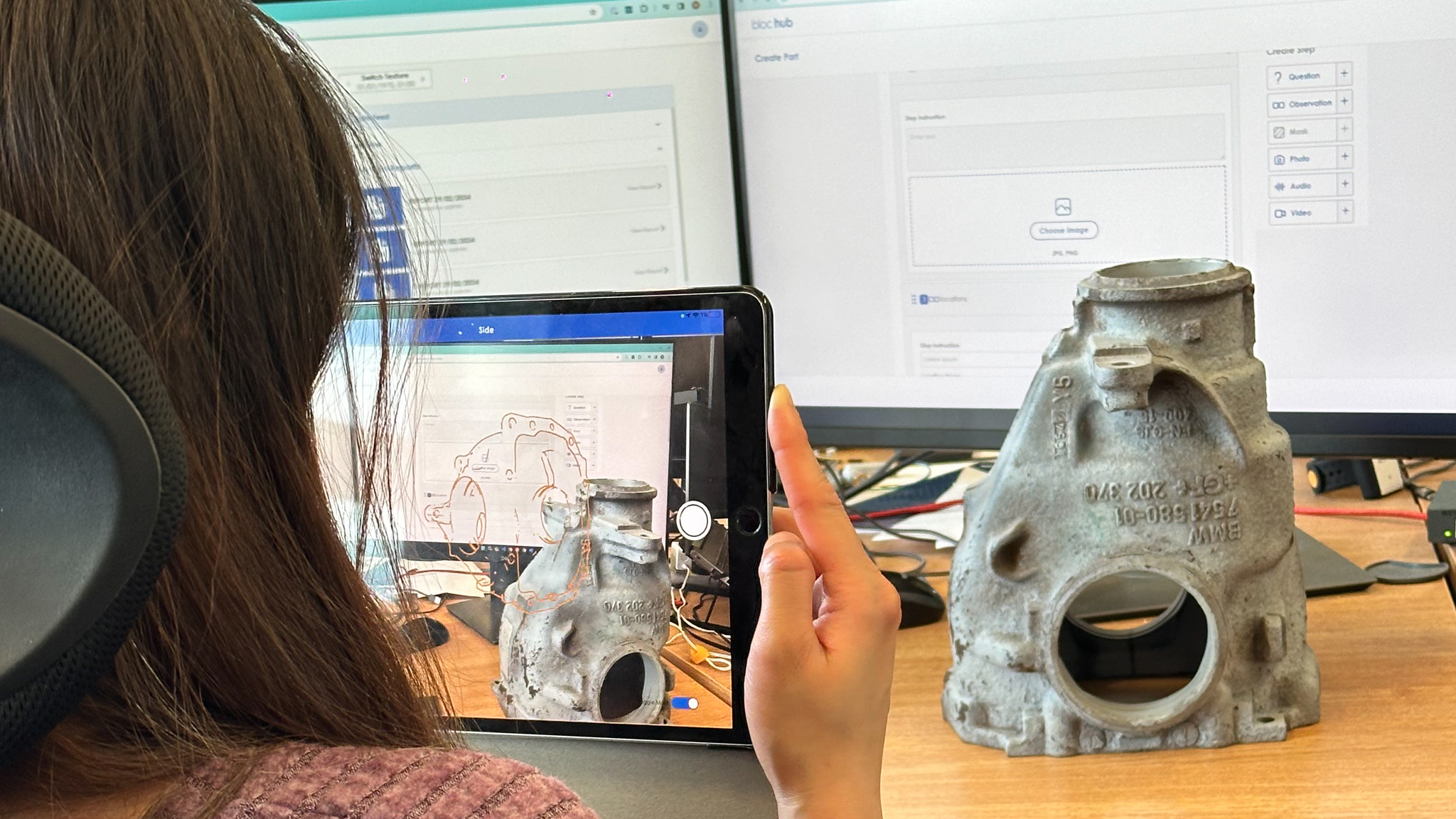

The company’s new “Inspector” product is already helping to turn manual visual inspections into intelligent data. The tool enables users to capture, track and manage the current and historical states of components through images, video or voice notes.

It collates and analyses results across an entire fleet to give a complete understanding of performance and common part faults. The study will make creating high-quality 3D content within the application quicker, easier and more intuitive, enabling Aerospace Inspectors to create their own 3D digital representations of parts without the need for CAD models – instead using only a smart device's camera.

A cutting-edge 3D imaging technology called NeRF (Neural Radiance Fields), will be harnessed to drive the digital transformation of aerospace inspections as part of new research. The project is being funded by the Aerospace Technology Institute (ATI) and the National Aerospace Technology Exploitation Programme (NATEP), with research being carried out by our digital solutions team and the University of Derby.

This research collaboration will explore the use of NeRFs to semi-automatically transform imagery and videos of advanced aerospace parts into high-quality 3D digital representations. These can be used to track the condition and degradation of such parts over time in order to enhance efficiency and decision-making within quality inspection and airline fleet management.

NeRF is a cutting-edge technique that generates 3D representations of an object from a partial set of 2D images by using advanced machine learning. The technology is designed to offer a generalised approach to 3D object modelling and can struggle to handle highly complex geometries such as specialised aerospace components. As part of the research collaboration, this research is focused on improving the speed and performance of the NeRF algorithm to support its application within the high-tech aerospace industry, improving processes forever.

INSPECTOR

We have supported the aerospace sector for over 20 years and specialise in developing operational and data-driven solutions that help to streamline and improve processes, such as digital twin and Internet of Things applications.

The company’s new “Inspector” product is already helping to turn manual visual inspections into intelligent data. The tool enables users to capture, track and manage the current and historical states of components through images, video or voice notes.

It collates and analyses results across an entire fleet to give a complete understanding of performance and common part faults. The study will make creating high-quality 3D content within the application quicker, easier and more intuitive, enabling Aerospace Inspectors to create their own 3D digital representations of parts without the need for CAD models – instead using only a smart device's camera.

-small-bloc-digital.jpg)